Oil & Gas Well Stimulation

OEI is the proud leader in offering unique, customer-centric filtration solutions to well-servicing equipment manufacturers and end users. OEI continuously innovates to provide highly-effective cleanable filtration for systems that can not accommodate conventional filters due to either flow or space restrictions. OEI has proven success protecting high-pressure pumps,compressors and injectors as well as standard systems such as hydraulics, reservoirs, lube oils and fuels.

FEATURED CASE STUDY

PROVEN RESULT: Break in Wear Removed, All Systems Protected

CUSTOMER

STEP ENERGY / NATIONAL OILWELL VARCO

LOCATION / DATE

CALGARY AB, CANADA 2018

EQUIPMENT

NEW-BUILD N2 PUMPER

APPLICATION / FLUID

TOTAL-PROTECTION KIT

CHALLENGE

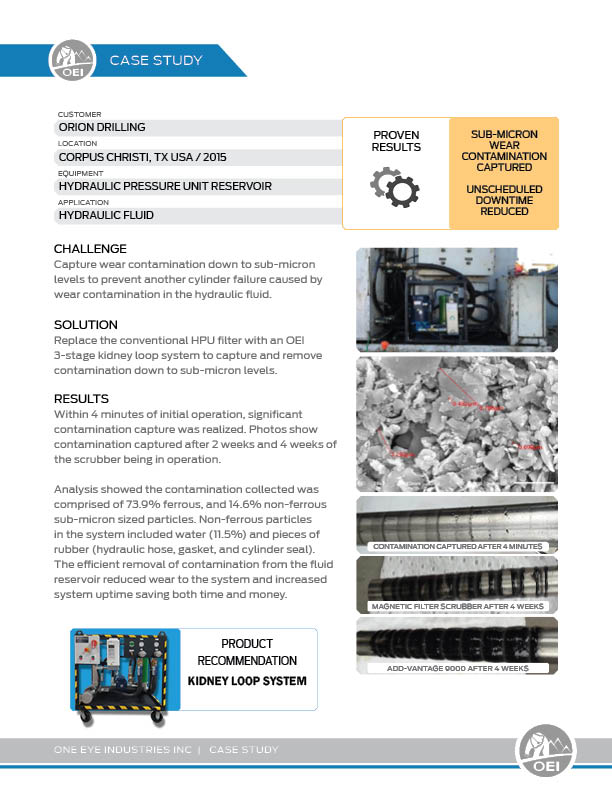

STEP Energy Services (STEP) and National Oilwell Varco are reliability leaders in the oil and gas downstream industry. STEP and NOV have partnered with OEI on mulitple occasions to design and manufacture well servicing equipment that is outfit with state-of-the-art magnetic filtration solutions with the intent to drive reliability, safety, and cost savings.

STEP Energy Services holds themselves to their own high expectations for exceptional client services; through accountability, technical knowledge, purpose-built equipment, and industry leading proactive maintenance programs. The team at National Oilwell Varco pride themselves on harnessing experience and innovation to minimize risk, increase uptime, and improve performance for drilling operations around the world.

As part of their proactive maintenance program, STEP Energy Services deploys OEI magnetic filtration on all major equipment components to protect fluids, gases, and lube oils against sub-micron wear contamination. To ensure the highest-quality builds, National Oilwell Varco collaborates with OEI to design filters that meet their new-build equipment installations, space restrictions, and fluid application parameters.

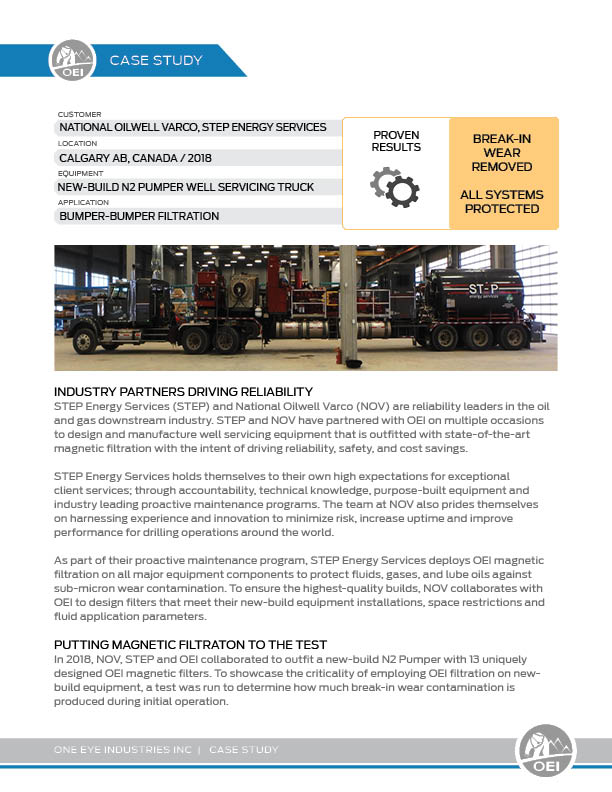

TEST

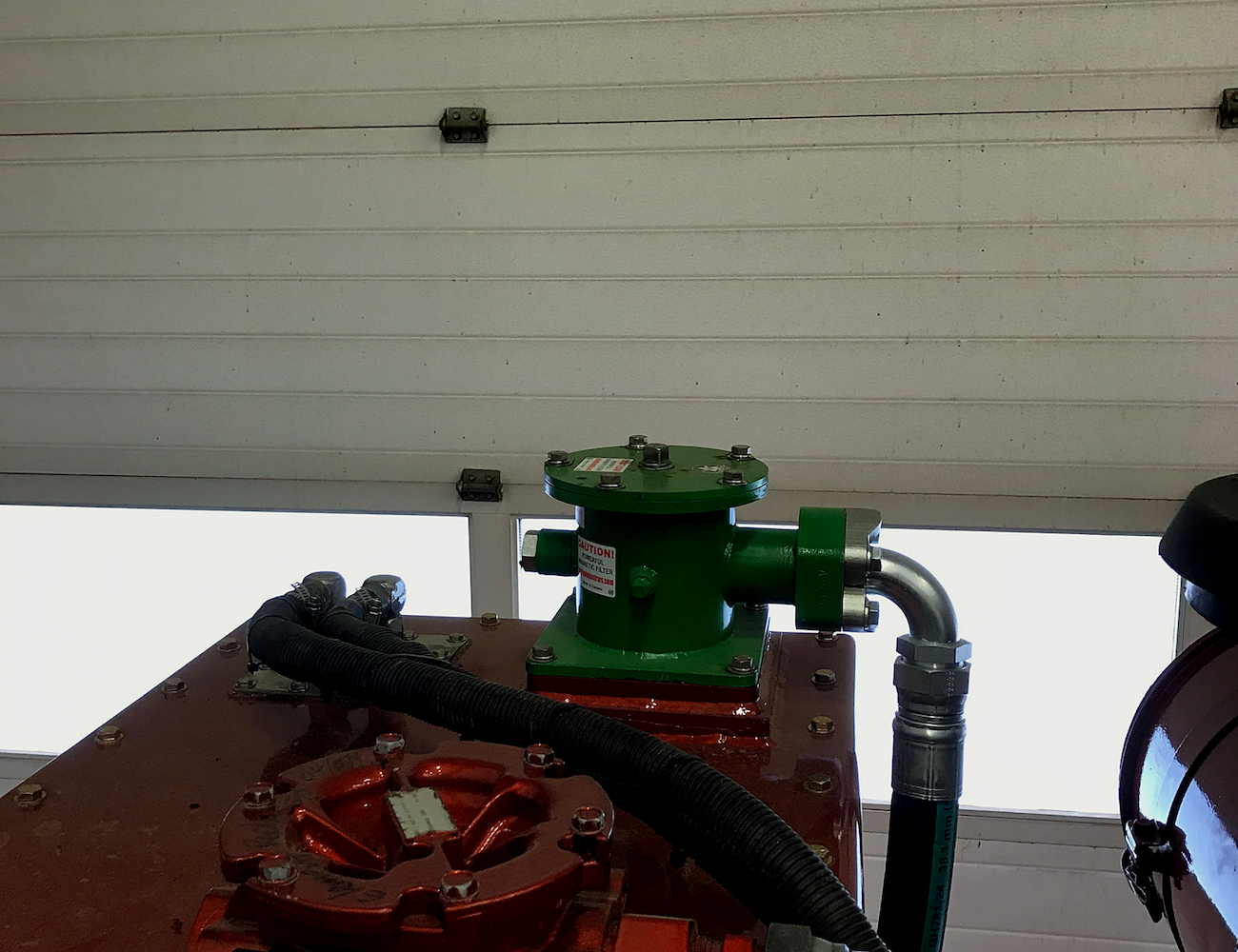

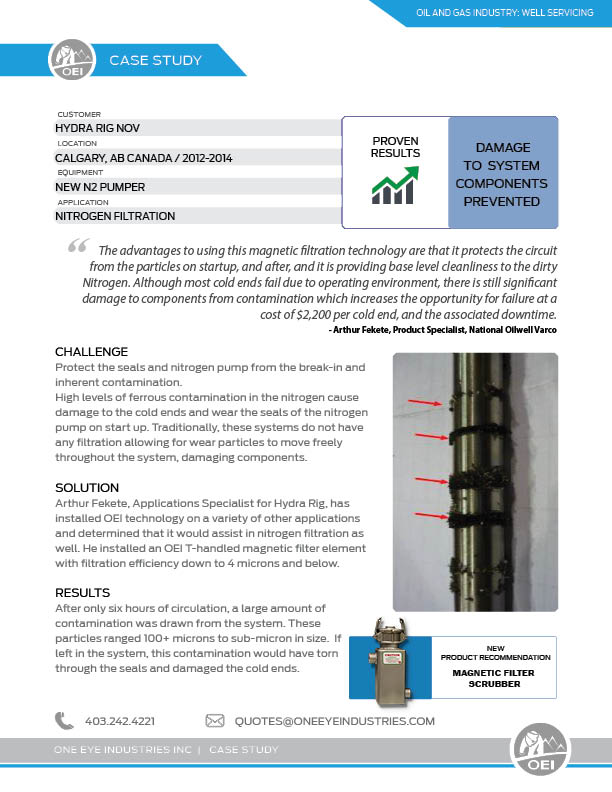

In 2018, NOV, STEP and OEI collaborated to outfit a new-build N2 Pumper with 13 uniquely designed OEI magnetic filters. To showcase the criticality of employing OEI filtration on new-build equipment, a test was run to determine how much break-in wear contamination is produced during initial operation. Without immediate protection, as soon as equipment enters service, break-in wear contamination down to 4 microns and below would damage critical equipment components and reduce operating life.

Run the new-build N2 Pumper for 5 minutes with 13 magnetic filters deployed on the various fluid applications. Evaluate how much break-in wear is produced to determine the criticality of magnetic filtration at the OEM level.

RESULTS

After the first 5 minutes of runtime, every magnetic filter installed pulled significant amounts of wear contamination from the system. Without magnetic filtration, the contamination would continue to circulate through critical systems, wearing on components and causing premature failures. If left in the system, the break-in wear contamination would build throughout the N2 Pumper, damaging close tolerance components such as bearings, injectors, and valves.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to

determine which product is right for you.

Request a Quote

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com

Tesco Top Drive

Tesco Top Drive New N2 Pumper

New N2 Pumper  Canyon Technical Services

Canyon Technical Services