PROVEN RESULTS IN

DEMANDING APPLICATIONS

What is your application?

HYDRAULICS

Protect your hydraulic equipment from fluid degradation. Sub-micron filtration is critical to protect valves and bearings which ensures your hydraulic systems perform to expectations.

Oil and Gas Well Servicing:

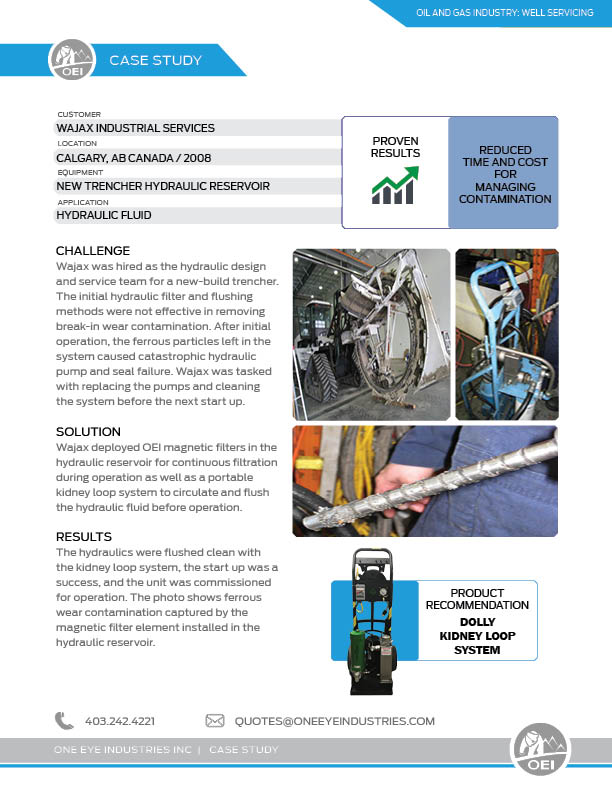

Trencher Hydraulic Fluid Reservoir

Oil and Gas Well Servicing:

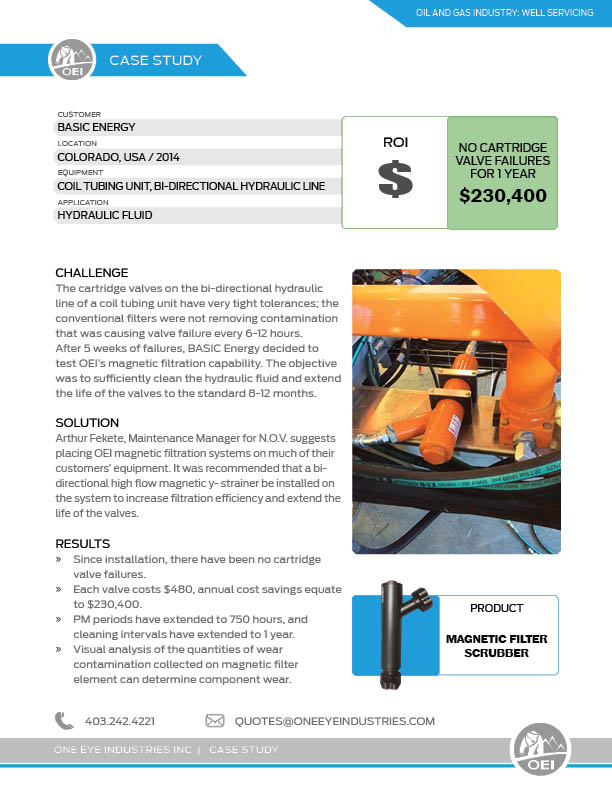

Bi-directional Hydraulic Line

Oil and Gas Well Servicing:

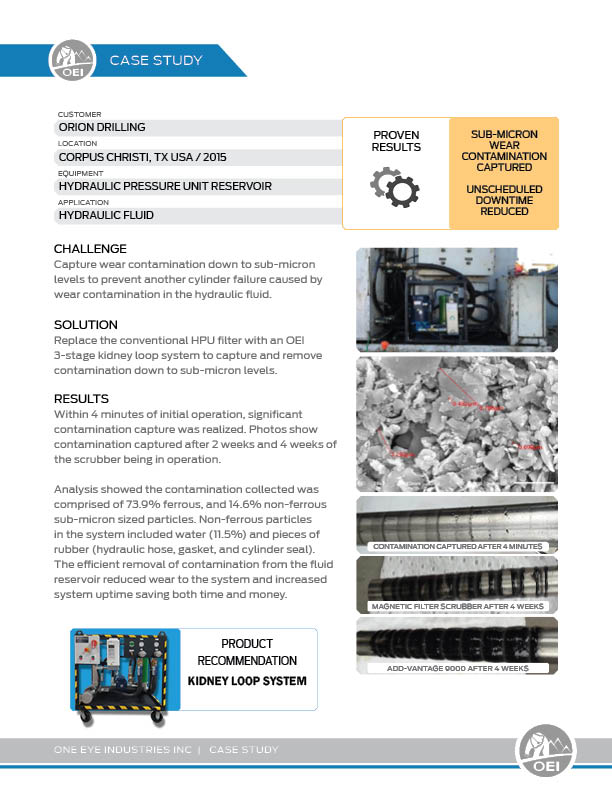

Orion HPU Kidney Loop

Mining:

Mining:

Shovel Hydraulic Fluid ISO

PNEUMATICS

Protect instrumentation such as valves, bearings, pneumatic motors, and air breathers. Solid particles contaminate air systems through ambient air intake, corrosion, and carbon build-up.

Manufacturing:

High-pressure Air Compressor

Manufacturing:

Pneumatic Control Valve

PUMPS

Protect pump components from wear contamination with the assurance that your pump won’t cavitate. OEI filters operate with minimal flow restriction so they don’t starve pumps.

Water Treatment:

Campground Water Pump Protection

Oil and Gas Well Servicing:

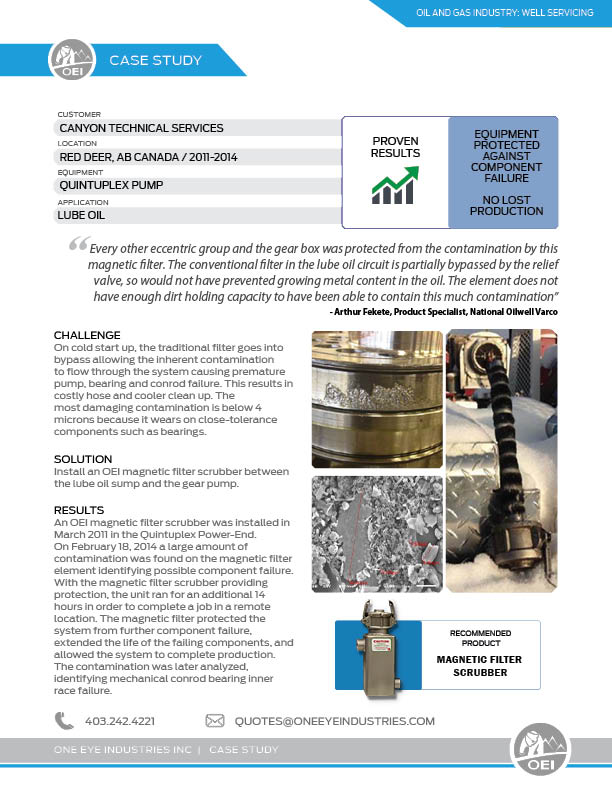

Quintuplex Pump Protection

Pulp & Paper:

Slurry Pump protection

ENGINE OIL

Extend service intervals. OEI technology applies to natural gas, diesel fuel, and steam turbine engines. The OEI advantage is high holding capacity filters with continuous filtration in bypass.

Manufacturing:

Diesel Engine Extended Oil Changes

Military:

Navy Ship Engine Oil Filtration

Mining:

Haul Truck Engines and 1.4 Million Dollar Savings

Mining:

Cancelling Engine Rebuild

Municipality:

Public Transport Bus Oil Change Extension

Oil and Gas Plant:

3512 Pioneer New Engine Lube

Pulp & Paper:

Log Loader Engine

Transportation:

Diesel Locomotive Engine

Transportation:

17 Years of Engine Protection

Transportation:

Luxury Yacht Engine Protection

Transportation:

1000+ Hour Oil Change Intervals

Transportation:

Truck 10,000 km Oil Change Intervals

ENGINE COOLANT

Extend service intervals. OEI technology applies to natural gas, diesel fuel, and steam turbine engines. The OEI advantage is high holding capacity filters with continuous filtration in bypass.

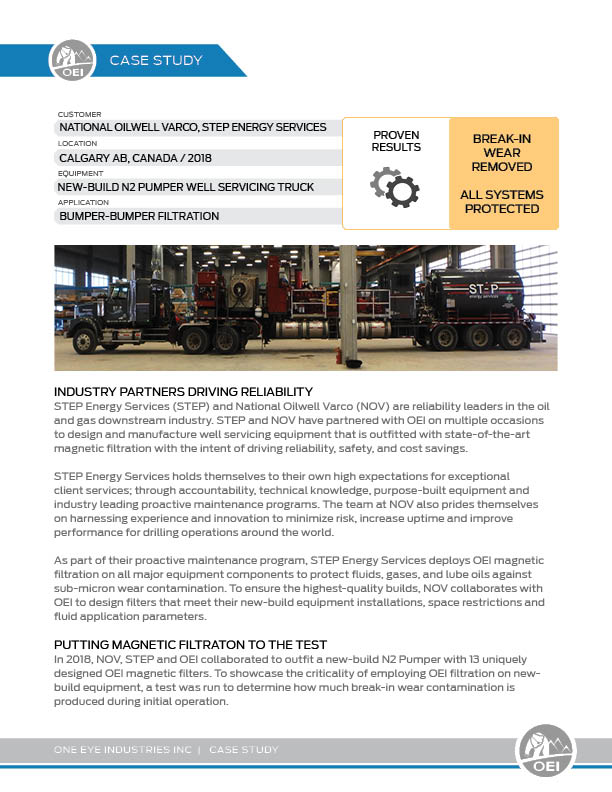

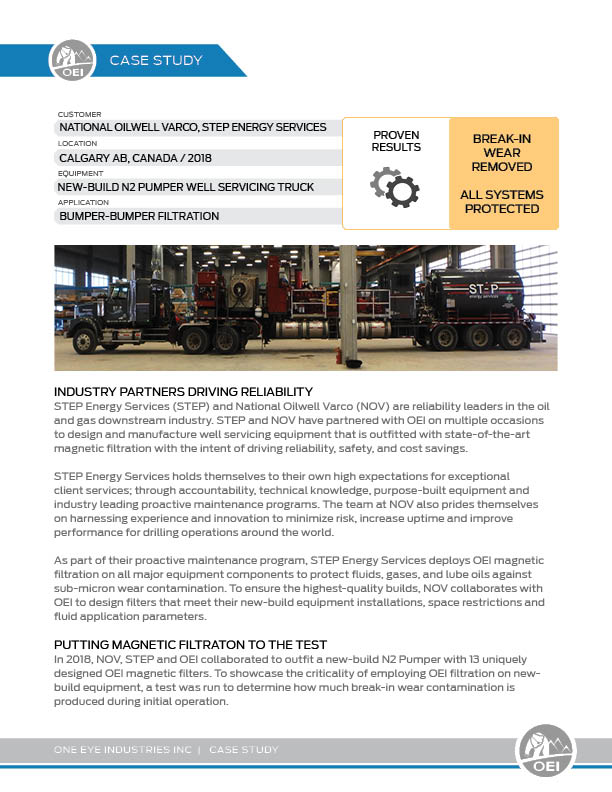

Oil and Well Servicing:

N2 Pumper Break-in Wear

ENGINE FUEL

Extend service intervals. OEI technology applies to natural gas, diesel fuel, and steam turbine engines. The OEI advantage is high holding capacity filters with continuous filtration in bypass.

Military:

Mexican Navy Ship Fuel System Protection

Transportation:

Cummins Engine Diesel Fuel Test

Transportation:

Kenworth Truck 17 Years of Engine Protection

Transportation:

Luxury Vessel Fuel Filtration

Transportation:

Municipal Transport Bus Fuel Filtration

Transportation:

N-14 Cummins Engine Fuel Test

Transportation:

The 1000+ Hour Oil Change Interval Challenge

Transportation:

Transoceanic Yacht Fuel Pump Protection

FUEL SYSTEMS

Reduce emissions by protecting high-pressure fuel injectors from sub-micron wear contamination that wears nozzles and degrades engine performance and burn efficiency.

Municipality:

Public Transport Bus Oil Change

Transportation:

Transportation:

Farm Bulk Diesel Fuel Tank

Municipality:

Municipality:

Transport Bus Fuel Dispenser

Power Generation:

Power Generation:

Generator Diesel Fuel

Oil and Gas Well Servicing:

Top Drive Diesel Fuel

Power Generation:

Electric Motor Generators Fuel Filtration

COOLANT & GLYCOL SYSTEMS

Protect engines from glycol leakage that leads to sludge deposits, oil-flow restriction, cold engine seizures, additive precipitation, formation of corrosive acids, and oil balls.

Oil and Gas Plant:

Glycol Gas De-Hydration

GEARBOXES

Put an end to wear contamination that causes 80% of your equipment failures. Prevent the degradation of gearbox components that leads to catastrophic system failure.

Transportation:

Transmission Run Stand

Power Generation:

Power Generation:

Coal Loading Gate

Mining:

No. 2 Dragline Gearboxes

Mining:

930E Wheel Motor

Transportation:

Ski-lift Gearbox Reliability

Mining:

16H Grader Break Failure

Mining:

C10 & C11 Final Drives

Power Generation:

Wind Turbine Reliability

COMPRESSORS

Eliminate engine lube oil degradation. Protect close tolerance components, like seals and valves, that are critical to the operation of compressors.

Oil and Gas Plant:

Screw Compressor Lube Oil Analysis

Food Processing:

Ammonia Compressor Lube Oil

Manufacturing:

High-Pressure Air Compressor

Food Processing:

Orogel Ammonia Compressor Lube Oil

EQUIPMENT KITS

Protect mobile equipment bumper to bumper. Magnetic filtration kits protect all system fluids: coolant, hydraulic fluid, water, fuel, and lube oil.

Transportation:

1000+ Hour Oil Change Intervals

Oil and Well Servicing:

N2 Pumper Break-in Wear

Municipality:

Houston's Emergency Vehicles

Transportation:

17 Years of Engine Protection

WATER SYSTEMS

Protect utility and process water from rust and corrosion contamination. Common applications are cooling lines, boiler feed lines, reservoirs, and process water lines.

Building Operations:

BOW Tower HVAC Outfitting

Building Operations:

Radiant Floor Heating System Reliability

Water Treatment:

Calendaring Hot Water System

Water Treatment:

Coolant Flush Water Mechanical Seals

Water Treatment:

De-mineralized Water Injection System

Water Treatment:

Hot Rolling Mill Coolant Flush Water

Water Treatment:

Improved Water Quality for Boiler

Water Treatment:

Kazakhstan Municipal Water Quality Test

Water Treatment:

Municipal Water Quality Standards

PARTS WASHERS

Move away from conventional bag filters to improve product quality and earn repeat sales. Contaminated washer fluid is the reason why machined products fail painting and final quality control.

Manufacturing:

Parts Washer Quality Control

PRODUCT LINES

Successfully filter pulp slurry, production materials, foods, or fluids. OEI filters are designed to meet application parameters such as flow rate, viscosity, and pressure. OEI has proven success improving final product quality in various production applications.

Food Processing:

Food Processing:

Fresh Product Conveyor

Food Processing:

Food Processing:

Bean Processing Line

Food Processing:

Food Processing:

Corn Feed Mixer

Food Processing:

Tobacco Blender

Food Processing:

Candy Product Line

Food Processing:

Chocolate Product Line

Pulp & Paper:

Slurry Pump Protection

MILLING MACHINES

Improve the quality of cooling/cutting oil used in your CNC machines to extend operating life, ensure efficient heat transfer, prevent re-cutting or welding of filings, and reduce the risk of tooling fracture.

Manufacturing:

Milling Machine Cooling

RESERVOIRS

Protect your mobile and stationary equipment by employing OEI magnetic filtration to remove the contamination that degrades components and builds up sludge in reservoirs and sumps.

Food Processing:

Food Processing:

Cavenish Farms Fry Oil Reservoir

Food Processing:

Food Processing:

Indonesia Corn Feed Mixer

Manufacturing:

Manufacturing:

Mobil 220 Lube Oil Reservoir

HEAT EXCHANGERS

Improve heat transfer efficiency by capturing the particle contamination sourced from airborne entry, corrosion contamination, and mineral deposits.

Manufacturing:

High-Heat Transfer System

CHEMICALS & GASES

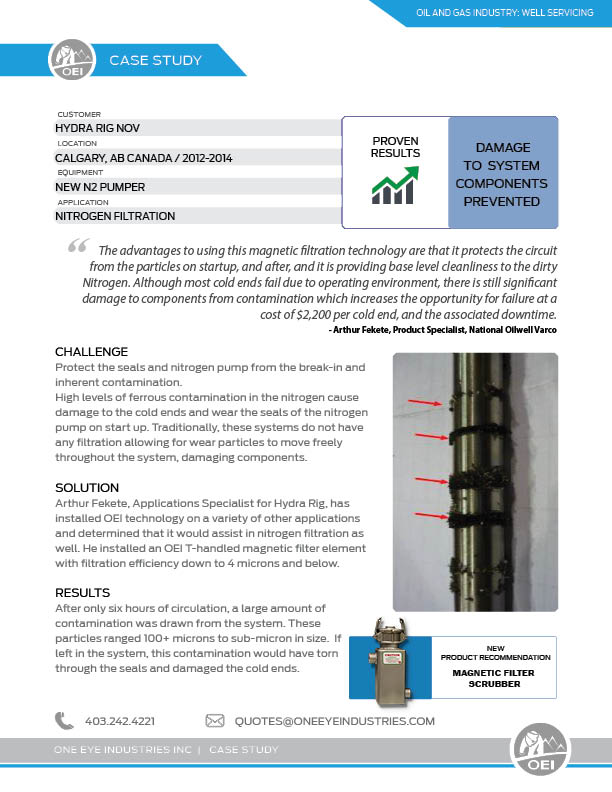

Protect injectors, pumps and compressors from contamination in caustic chemicals and high-pressure gases.

Oil and Gas Well Servicing:

N2 Pumper Liquid Nitrogen

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com